Our Technical Process

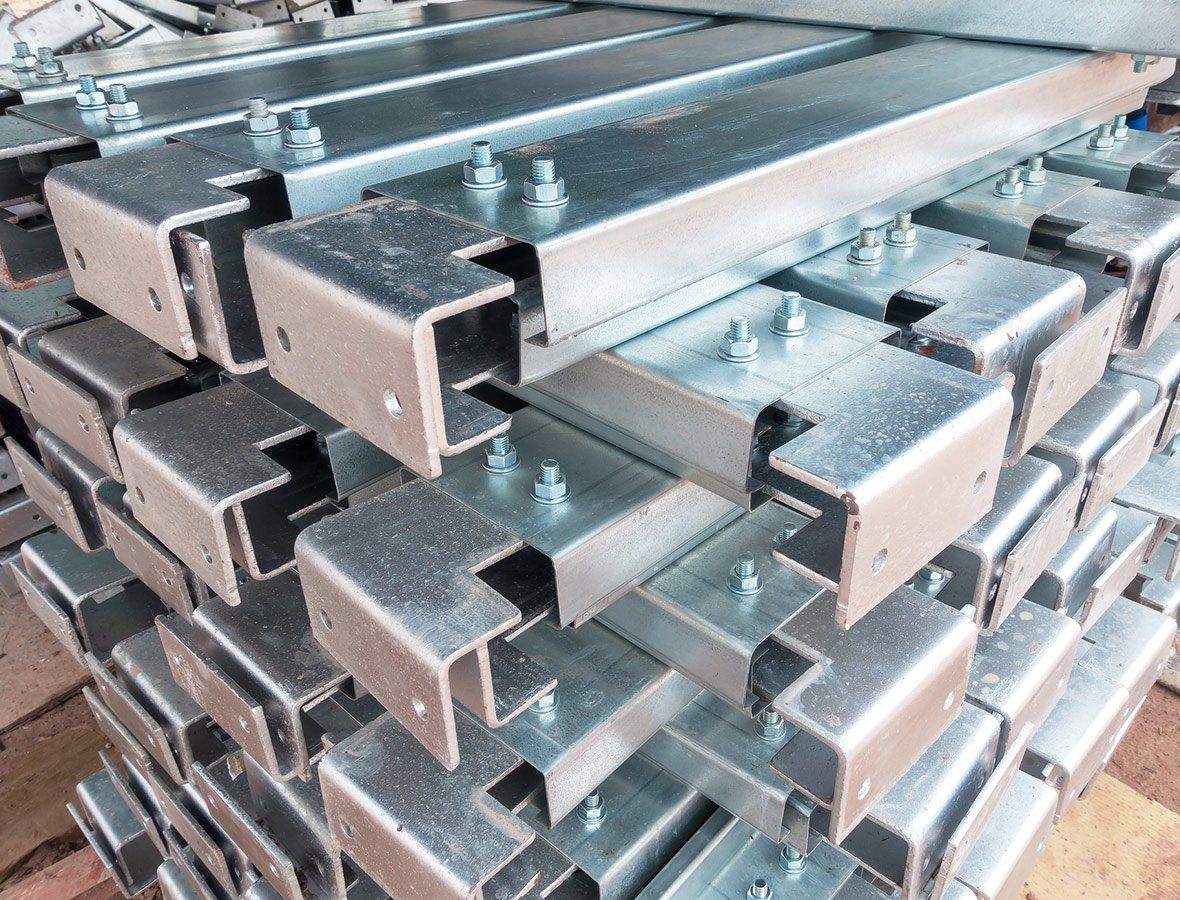

Corrosion protection is a necessity for fabricated iron and steel metals. During the galvanizing process, molten zinc reacts with the surface of the base material to form an inner layer of protection against corrosion. The standard coating has a typical life of anywhere from ten to twenty-five years in urban environments to more than fifty years in rural conditions.

Kettle Dimensions

Our largest kettle size is 44-1/2' x 7' 6" x 5' 10"

Galvanizing Resources

Have a question? We’re here to help.

Technical support on innovative applications and technological developments in hot-dip galvanizing for corrosion protection.

-

Guides/Publications

Hot-Dip Galvanizing for Corrosion Protection: A Specifier’s Guided

- Corrosion and damage caused by corrosion are costly. Hot-dip galvanized steel can help combat corrosion. Learn about the Consideringproperties and performance of HDG steel and how galvanizing can enhance a project.

Design of Products to be Hot-Dip Galvanized After Fabrication

- Achieving a high-quality hot-dip galvanized coating starts with proper design. Learn how to incorporate the best design practices that promote higher quality products with reduced cost and shorter turnaround times.

Inspection of Hot-Dip Galvanized Steel Products

- Inspection of hot-dip galvanized steel is required to confirm applicable specification requirements are in compliance for optimal durability and performance of the galvanized product. Learn about the HDG inspection process.

Hot-Dip Galvanizing Costs Less, Lasts Longer

- When selecting a corrosion protection system for a given project, it is paramount to consider more than just the initial cost. Considering the life-cycle cost of maintaining a corrosion protection system provides a more accurate prediction of the project’s impact on future generations.

Hot-Dip Galvanized Coating Appearance

- HDG steel may have a variety of different initial appearances, including bright and shiny, dull, spangled, mottled, or matte gray. Learn more about the causes and concerns relating to HDG steel’s appearance.

-

Tools/Calculators

- The Zinc Coating Life Predictor (ZCLP) is a tool that estimates the corrosion rate of zinc in various environments using statistical methods, neural network technology, and an extensive worldwide corrosion database.

-

Frequently Asked Questions (FAQs)

- The corrosion resistance of zinc coatings is proportional to the thickness of the coating but varies with the environmental exposure conditions. Each environment affects hot-dip galvanizing differently based on a unique set of corrosion variables.

- The hot-dip galvanized coating is primarily comprised of zinc and zinc alloys and is sometimes placed in contact with different metals. This creates the possibility for galvanic corrosion that depends on the position of the other metal relative to zinc in the galvanic series, and to a lesser degree on the relative size of the surface area of the two metals in contact.

-

HDG vs. Competitors

General Hot-Dip Galvanizing vs. Continuous Sheet Galvanizing

- This one-page handout is a comprehensive side-by-side comparison of general (batch) after-fabrication hot-dip galvanizing and prefabricated, continuous galvanized sheet.

Hot-Dip Galvanized Rebar vs. Epoxy-Coated Rebar

- This comprehensive handout compares hot-dip galvanized rebar with epoxy-coated rebar including a side-by-side comparison of performance, a detailed account of concrete corrosion, and galvanized rebar bridge case studies.

Hot-Dip Galvanized Steel vs. Paint

- This handout is a detailed cost comparison of hot-dip galvanizing and paint. The handout features a side-by-side comparison of weather dependency, bond strength, service life, and much more. It also compares the initial cost and maintenance cost of hot-dip galvanizing with four paint systems.

Hot-Dip Galvanized Steel vs. Weathering Steel

- This one-page handout provides a side-by-side comparison of hot-dip galvanized steel and weathering steel. The analysis includes fatigue life, inspection, appearance, corrosion rate, and much more. In addition, the handout explains the performance of both steel types in five different environmental conditions.

Hot-Dip Galvanized Steel vs. Zinc Spray Metallizing

- This one-page handout is a detailed comparison of hot-dip galvanizing and zinc spray metallizing. The publication features a side-by-side analysis of weather dependency, bond strength, service life, and much more.

Hot-Dip Galvanized Steel vs. Zinc-Rich Paint

- This handout is a detailed comparison of hot-dip galvanizing and zinc-rich paint. The handout features a side-by-side analysis of weather dependency, bond strength, service life, initial/maintenance costs, and much more.

Hot-Dip Galvanized Steel vs. Mechanical Plating

- This one-page handout is a comprehensive side-by-side comparison of general (batch) after-fabrication hot-dip galvanizing and mechanical plating.

All Rights Reserved | Southwest Galvanizing, Inc.